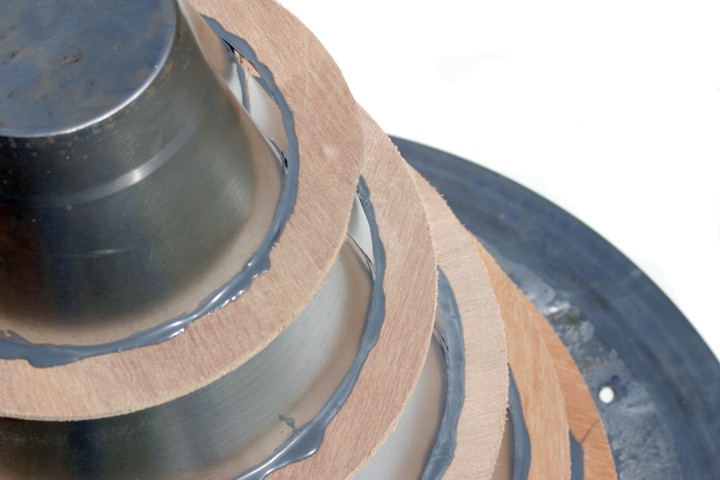

PoP-T06s cone stiffeners before testing.

PoP-T06svideo of buckling process, laser scanning, and final failure by ring de-bonding

PoP-T06s was tested by slowly increasing the pressure. The ring configuration was the same

as PoP-T05s. The initial buckling was between the flange and the first stiffening ring.The bucking was nearly elastic, and the shape of the cone returned to near its orginal

shape upon unloading. Laser scans were done on the cone prior to testing, and also while

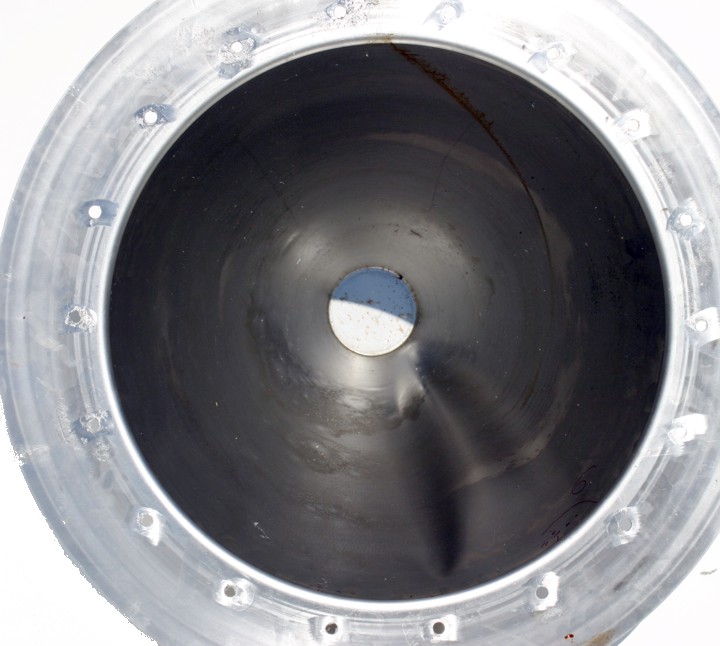

the buckles were formed. This cone was loaded and unloaded several times.The final failure was a progressive stiffening ring de-bonding failure. The first ring to

debond was the largest (top) ring, and subsequent rings debonded within a few seconds

of each other at a static pressure.

PoP-T06s cone stiffeners before testing.

PoP-T06s cone with final failure mode shown, interior view.

PoP-T06s cone with final failure mode shown, exterior view.

PoP-T06s cone with final failure mode shown, exterior view.

PoP-T06s cone with final failure mode shown, exterior view.

PoP-T06s cone exterior view.

PoP-T06s cone with final failure mode shown, interior view.