The 2005 project was focused on determining the affect of structural stiffening on the initial buckling

pressure of the cones. Toledo Metal Spinning produced the cones as in the 2004 study, but this time

the cones were manufactured with a closed end by welding a cap on the end of the cone.Instrumentation upgrades for this round of tests include the use of an electric winch instead of a hand

winch, and the use of a computer controlled, relay switched air pressure valve.Due to a programming error in the data acquistion software related to the implementation of the computer

controlled pressure valve, the initial and ulitmate buckling pressures were not captured by the data

acqusition system. This error was corrected for subsequent tests. Fortunately, as a redundant data

acquisition technique, a video of one of the digital pressure gages was made during the test.A frame grab of the video and the max value function of the digital pressure gage showed that the

initial and ultimate buckling pressure was 1.25 psi.The T01-2005 cone was not stiffened, as the purpose of this test was to ensure that similar test

results would be obtained for these cones as for the previously tested cones. The laser range finder

was used on this test to obtain pre-test scans and also for mode shape deterimination.Strain gage rosettes were placed 25 inches into the cone (along the cone wall).

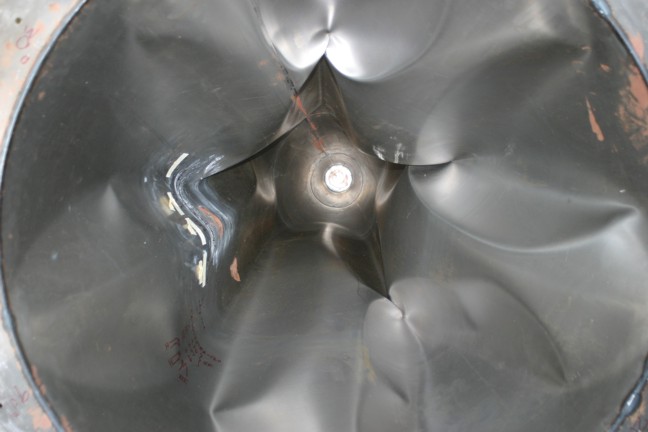

T01-2005 cone instrumented with strain gages.