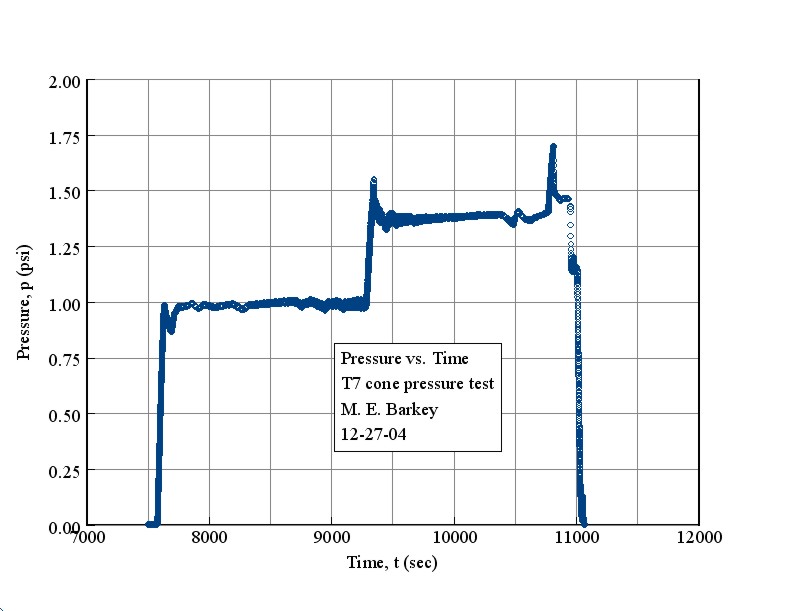

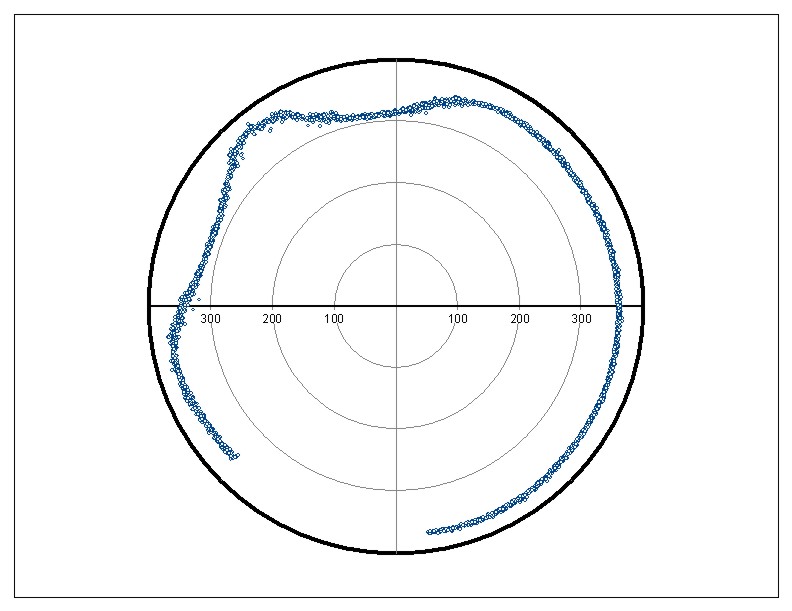

Results of

Mode-Shape Scans

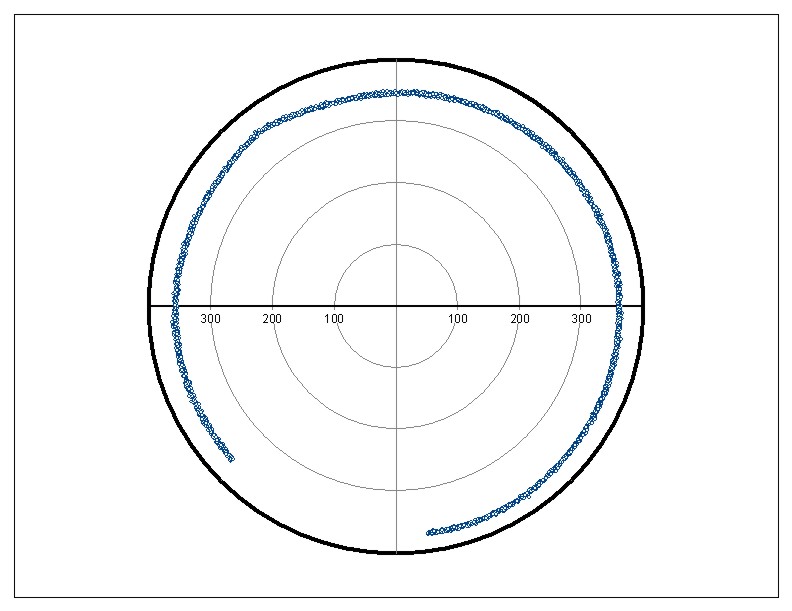

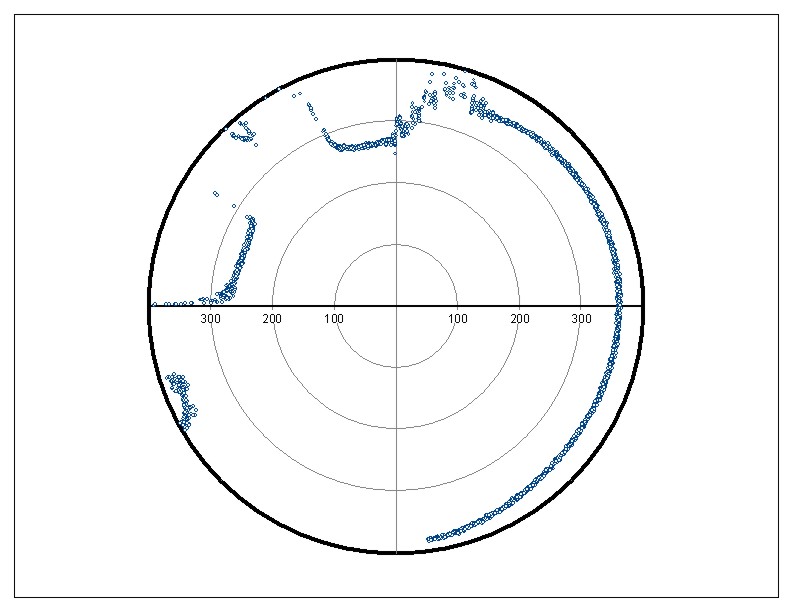

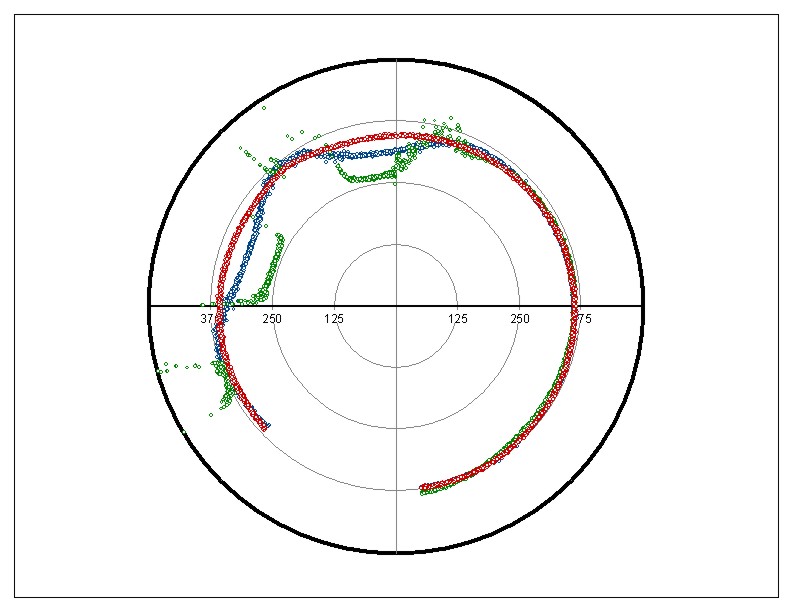

The following figures show the initial

shape and the results of the scans as portions of the cone

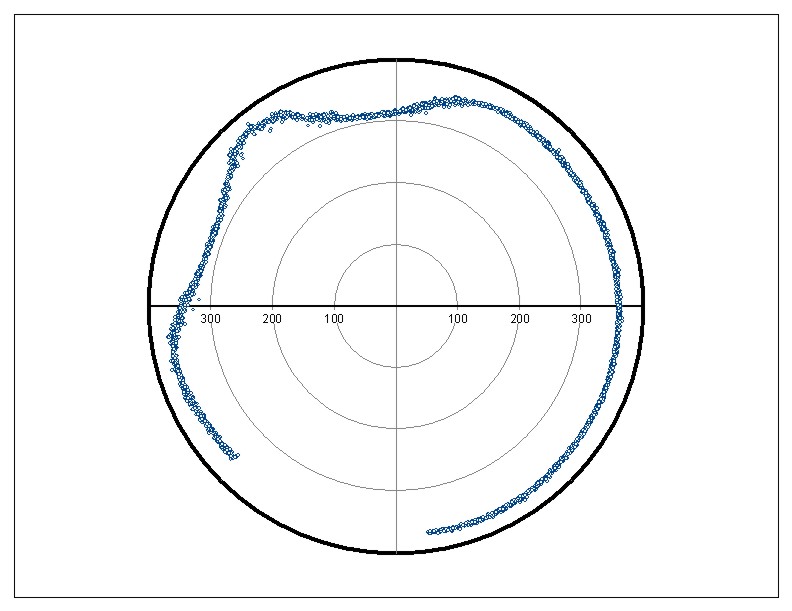

began to buckle. The second plot is

after the initial formation of two "lobes" of buckled cone.

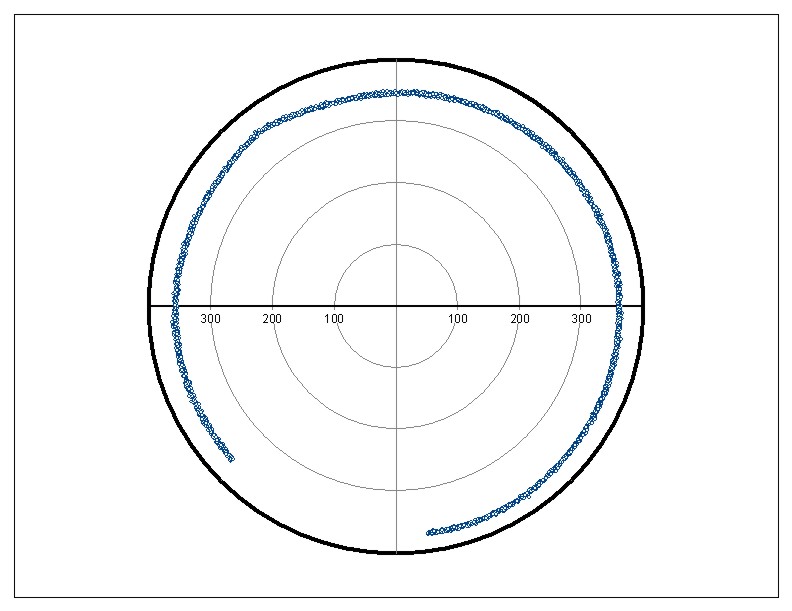

The third figure is after a total of four

lobes, at zero pressure after it had reached its collapse load.

These plots are polar coordinate plots at

a depth of about 610 mm into the cone.

As the deformation became more severe, the

laser scanner was unable to get a line of sight to every

part of the cone, so some spurious data was

introduced. Most of this has been filtered out, but some

remains and can be seen in the figures.